New Equipment under Service

The Veeco Fiji G2 Plasma Enhanced ALD has been installed, and on-site acceptance has been completed. The system is now available for NFF (CWB) users. At the same time, NFF (CWB) staff are working on recipe tuning and preliminary process test runs, including Al2O3, SiO2, TiO2, Ga2O3, AlN and TiN depositions. These processes will be made available to all NFF (CWB) users, and the cleanliness level of this ALD is classified as “Semi-clean”.

The setup of the ECM Greentech Tubestar batch-type furnace has been completed and is now available for NFF (CWB) users. This single-tube horizontal LPCVD furnace is designed for High-Temperature Oxide (HTO) deposition, with temperatures ranging from 730 °C to 950 °C. Compared to typical LPCVD processes, HTO demonstrates superior performance in film quality and conformality. The cleanliness level of this furnace is classified as “Clean”.

We would like to extend our gratitude to the Electronic Packaging Lab (EPACK Lab) for generously transferring their Disco DAD321 Dicing Saw to NFF (CWB). The system has since been refurbished by NFF (CWB) staff and is now ready to serve our users. The DAD321 is an easy-to-use automatic dicing saw machine capable of cutting up to 4-inch full silicon substrates in just minutes.

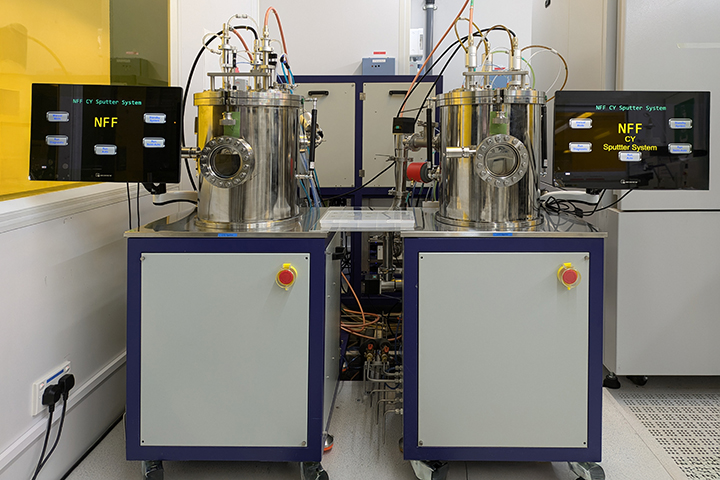

Following the setup of NFF-CY 1 Sputterer in 2023, two additional modified NFF (CWB) CY sputterers, CY 2 and CY 3, have been installed in NFF (CWB) Enterprise Center and will soon be available to NFF (CWB) users. Both magnetron sputtering systems are equipped with DC and RF power supplies, meeting our users' high demands for non-standard multi-layer thin film deposition processes.

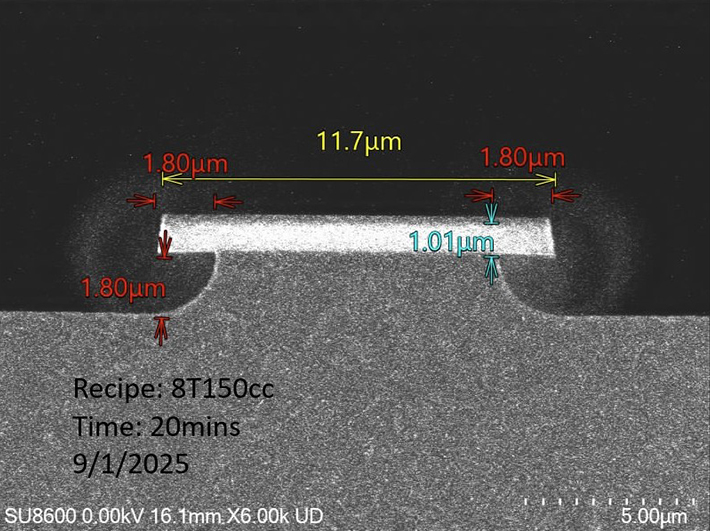

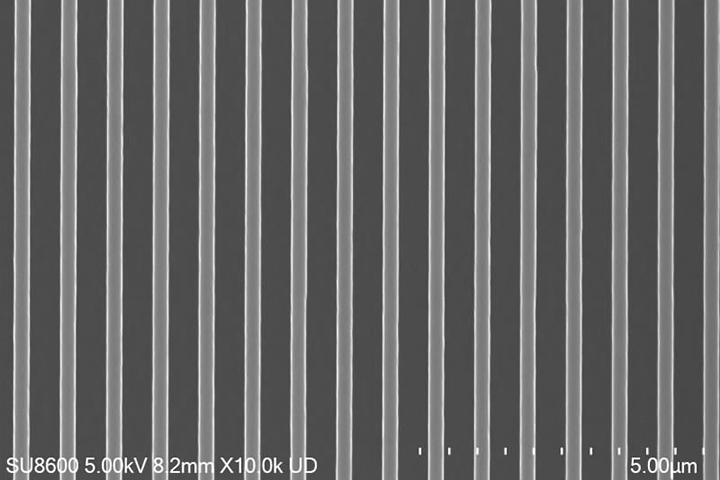

The Samco ICP-RIE system RIE-400iP was set up in September 2025 and will soon be available to NFF (CWB) users following equipment acceptance. This system features an advanced ICP source, a wide range of electrode temperature controls, and various process gas supplies. The ICP system is designed to meet users' high demands for etching non-standard materials, particularly for thin metal film etching, with the availability of chlorine and fluorine-based process gases.

The Memsstar ORBIS alpha XeF2 etching system is a compact silicon etch system that we purchased from one of our membership partners. This XeF2 etching system is ideal for silicon film release etching processes, utilizing xenon difluoride gas, and provides a valuable platform for MEMS research for our users. The system was released to NFF (CWB) users in February 2025 after completing full refurbishment work.

The Compact Nanoimprint Tool CNI v3.0 was released to NFF (CWB) users in April 2025. This desktop tool is designed for nano-imprinting and hot embossing, using a master to transfer micro- or nano-structures onto a substrate. The CNI tool is capable of performing both thermal and UV replication.