Publication Highlights

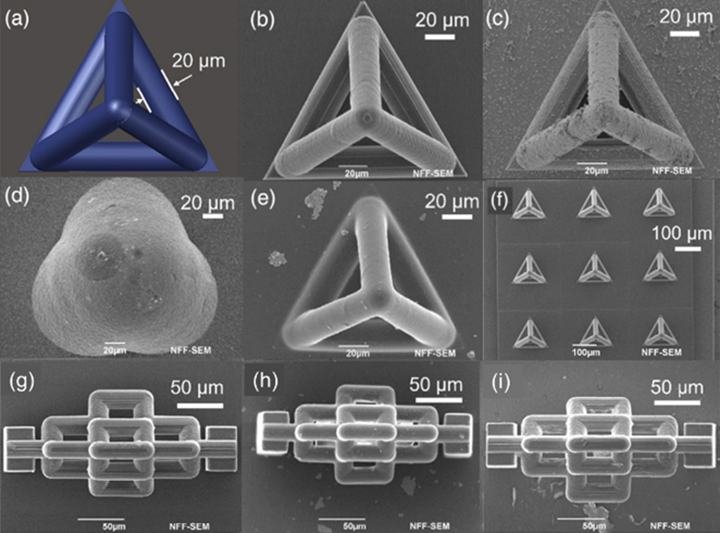

NFF(CWB) user Qiaoyi WANG’s paper, titled “Replicating 3D printed structures into functional materials,” was published in the Journal of Applied Polymer Science in April 2022. Qiaoyi WANG is supervised by Prof. Hongkai WU.

This work reported a convenient method to replicate 3D-printed structures into different functional materials. Consequently, many unprintable materials can be readily made into arbitrary geometry without re-engineering their printability or developing new 3D printing methods. These materials, such as polydimethylsiloxane, polyacrylamide and paraffin, are thermally curable, chemically crosslinkable, or can undergo liquid/solid phase change at mild temperatures. It shows a high fidelity during replication, and the replica can remain at high resolution of feature from a two-photon polymerization 3D printer, which can generate 3D structures with resolution down to 1 μm or even smaller.

In addition, electroless plating of metal in the internal walls of the mold can further shrink feature sizes in the final replica, which suggests an approach to obtain resolutions beyond the 3D printer at the start.

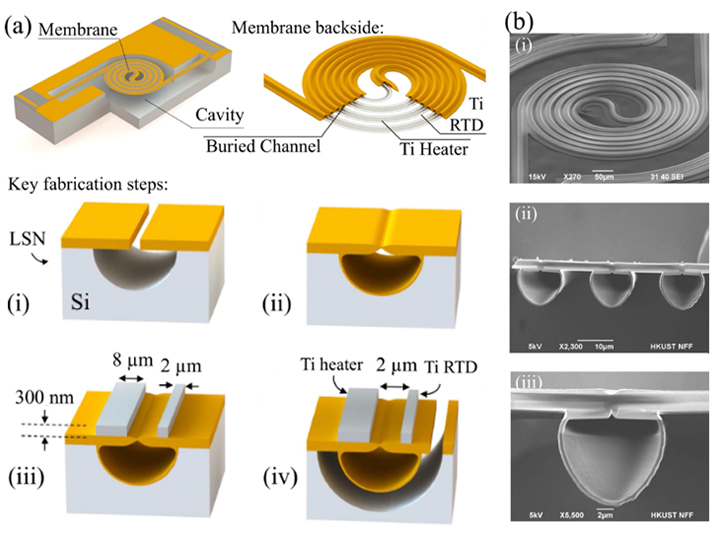

NFF(CWB) user Sheng NI’s paper, titled “A Sub-nL Chip Calorimeter and its Application to the Measurement of the Photothermal Transduction Efficiency of Plasmonic Nanoparticles,” was published in the Journal of Microelectromechanical Systems in October 2021. Sheng is supervised by Prof. Levent YOBAS.

This work demonstrated a microchip for differential measurements of aqueous samples in twin calorimetric arms with a sub-nL enclosed space. Each arm features a fluidic microchannel located in close proximity to a thin-film resistance thermometer and heater patterned on a low-stress SiN membrane held over a Si cavity with suspension beams. The chip exhibits a rapid response with a thermal time constant of less than 10 ms in atmosphere and a residual thermal conductance below 6μW⋅K−1, one of the lowest reported and accounts for the excellent sensitivity registered in vacuum up to 11 V⋅W−1.

These values are in good agreement with those predicted by modeling using finite element method, lumped-capacitance analysis and calorimeter electrothermal circuit simulation together with the measurement system. The specific heat capacity values of water, glycerin, and mineral oil were accurately measured by the chip.

Lastly, the chip calorimeter utility on the measurement of the photothermal transduction efficiency of plasmonic nanoparticles was demonstrated, providing the first account of a chip calorimeter being allied to accelerate the measurement of the photothermal transduction efficiency.