New Equipment and Process Capabilities

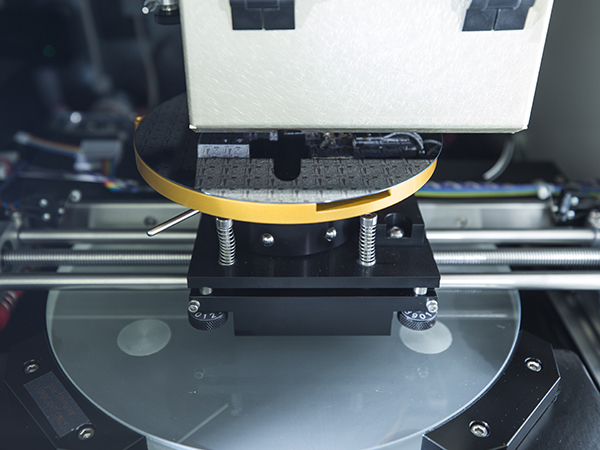

DRIE and the DRIE Process Center

A new Deep Reactive Ion Etcher (DRIE), SPTS Rapier, has been installed and in service in the recently launched NFF-DRIE Process Center (Rm. 2223). This equipment was funded by the Research Grants Council Collaborative Research Fund (RGC-CRF) equipment grant 2016/17.

The NFF acknowledges the generous supports and contributions from the HKUST’s Senior Management and Co-PIs as listed below:

Prof. Yang CHAI (PolyU), Prof. Ho Bun CHAN (HKUST),

Prof. Mansun CHAN (HKUST), Prof. Gary Shun Pan CHEUNG (HKU),

Prof. Hoi Wai CHOI (HKU), Prof. Zhiyong FAN (HKUST),

Prof. Kei May LAU (HKUST), Prof. Ricky Shi-Wei LEE (HKUST),

Prof. Yi-Kuen LEE (HKUST), Prof. Zhigang LI (HKUST),

Prof. Emma MACPHERSON (CUHK), Prof. Stella W. PANG (CityU),

Prof. Johnny K.O. SIN (HKUST), Prof. Weijia WEN (HKUST),

Prof. Man WONG (HKUST), Prof. Wenjing YE (HKUST),

Prof. Levent YOBAS (HKUST), Prof. Xuming ZHANG (PolyU).

In order to enhance the NFF’s Deep silicon etch capabilities, the NFF has launched a new DRIE Process Center in August 2018. In the Center, there are two DRIE etchers catering for different cleanliness levels. One of them is for non-standard DRIE etching processes, which the NFF did not support previously. With this extended DRIE process capability, the NFF can now support the whole range of cleanliness levels for DRIE processes. Moreover, a P-10 Step Profiler and a Nikon optical microscope are in service at the Center for in-line measurements and sample inspections.

Equipment

Three new equipment supported by the Equipment Competition 2017/18:

The NFF was awarded the Equipment Competition fund 2017/18 to purchase three new process and metrology equipment.

The NFF acknowledges the generous supports and matching funds from the HKUST’s Senior Management and Schools/Departments/Institutes:

Prof. Nancy Y. IP (Vice-President for Research & Graduate Studies),

Prof. Tim CHENG (Dean of Engineering),

Prof. Yang WANG (Dean of Science),

Prof. Bertram E. SHI (Electronic and Computer Engineering),

Prof. Christopher Y. H. CHAO (Mechanical and Aerospace Engineering),

Prof. I-Ming HSING (Chemical and Biological Engineering),

Prof. Michael S. ALTMAN (Physics),

Prof. Ho Bun CHAN (Physics),

Prof. Zhenyang LIN (Chemistry),

Prof. Qingping SUN (I2MS).

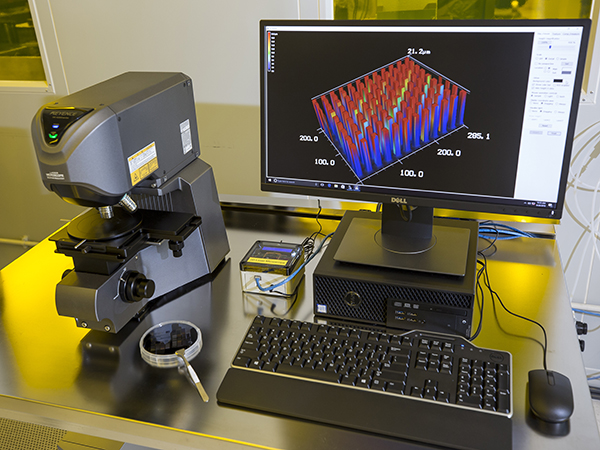

3-D Surface Profiler

A non-contact, high-speed and large-scanning-area Laser Surface Profiler (VK-X250K) from Keyence has been installed in the NFF Phase II laboratory. The profiler can significantly improve topological measurements of various substrates. Users can obtain their sample’s surface topographic images and analyze the acquired data within a very short time.

High-Resolution Optical Microscope

A high-resolution Nikon L200ND optical microscope has been installed in the NFF laboratory to facilitate a fast inspection after wafer processing.

Critical Point Dryer

A Tousmis Automegasamdri 915B Critical Point Dryer has been installed in the NFF Phase II laboratory for drying substrates fabricated with special structures after cleaning and rinsing.

P-7 Surface Profiler

A new P-7 Surface Profiler from KLA Tencor has been installed in the NFF laboratory. This profiler features a high accuracy and it is easy to operate.

In-house-built RIE

An in-house-built RIE etching system has been launched in service to address the constant needs of etchers for etching silicon, silicon dioxide and silicon nitride. This system is the result of a joint collaborative project between the NFF and the Design & Manufacturing Services Facility (DMSF), and led by the NFF Chief Technical Officer, Mr. LEE Man Wai.

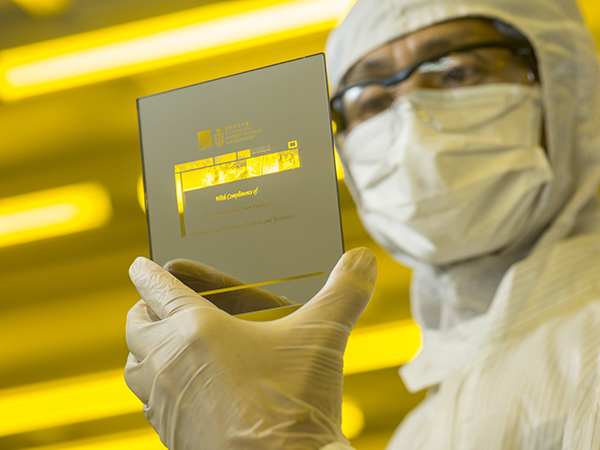

Phasing-out of Intertect ISI-2808 Mask Writer

After serving NFF’s users for more than two decades, we are phasing-out Intertect ISI-2808 Mask Writer. All mask writing jobs are now delivered by Laser Direct Writer (Heidelberg DWL2000) with a higher resolution and a higher throughput.