New Equipment and Process Capabilities

Enhancement for microfluidics research

One major initiative by the NFF is in strengthening the fabrication infrastructure for the research area of microfluidics. This is based on extensive consultations with major PIs in the area.

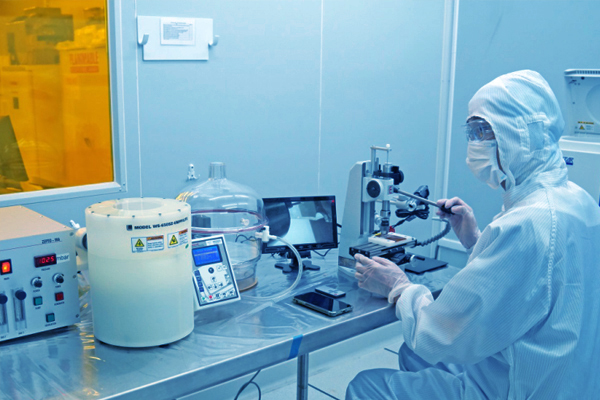

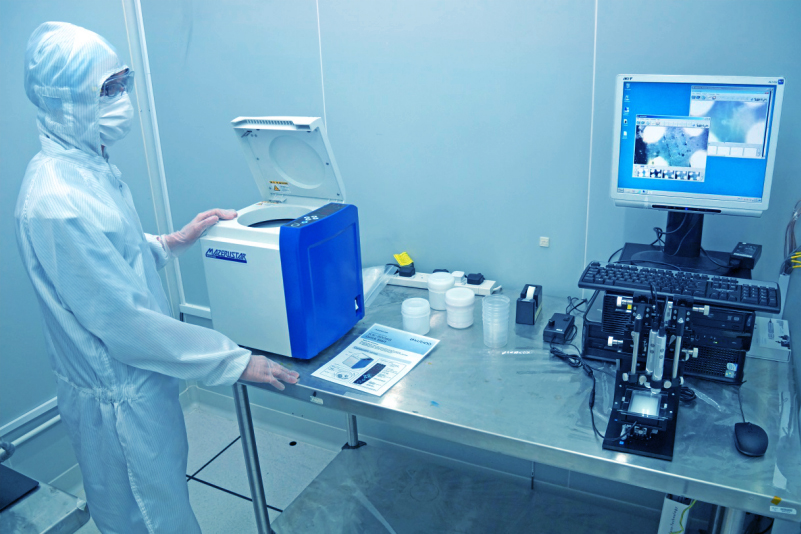

In order to enable the new service while minimizing contamination, we have designated a cleanroom space of 2.3 m × 2.8 m (class 1,000) in the Phase II lab and have installed the equipment for microfluidics processes, including Laurell WS-650SZ PMDS Spin Coater, Kurabo KK-300SS PDMS Planetary Mixer/Deaerator, Diener ZEPTO W6 Plasma Cleaner (0-50W), SYNEO PMDS hole Punch, Desktop PMDS Aligner, etc.

Equipment upgrade for the photolithography module

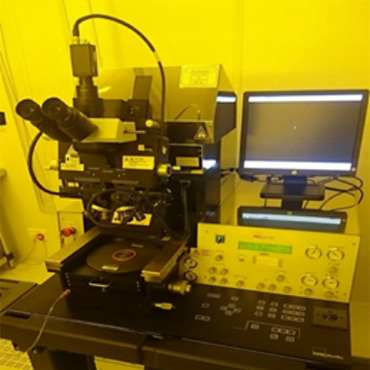

With the one-off re-capitalization budget support from the VPRDO in 2018/19, the NFF has acquired a re-manufactured Karl Suss MA6 double-sided aligner to replace the existing MA6 #1 aligner in the NFF-EC.

The NFF has completed the installation, machine evaluation and has offered equipment training of the remanufactured MA6 aligner in April 2019, and has released the system to users in May 2019.

The NFF has successfully applied for the Equipment Competition grant 2018/19 for a new wafer track system for photoresist coating and development (SVG88 wafer coating and development track) to replace the existing wafer track SVG86, which was installed in 1997.

The new wafer track SVG88 can handle both 4” and 6” round substrates. With additional sensors, the proposed system can process transparent substrates, which cannot be realized using the SVG86.