New Equipment and Process Capabilities

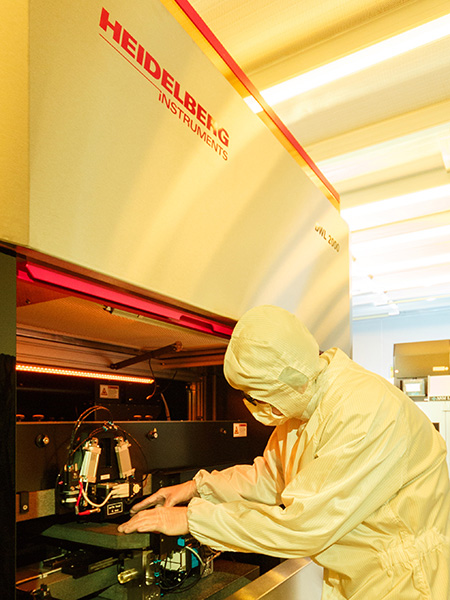

A Major Upgrade of the NFF’s Mask-Making Capability

The NFF has installed and launched the service of a new state-of-the-art Laser Lithography System (DWL2000 from Heidelberg Instruments) in the middle of 2017. Compared to the old laser lithography system, the new system features an increased process capability (down to a 0.5µm resolution) and a faster writing speed (4x faster). This enhancement can significantly boost the NFF’s mask-making capability.

The NFF acknowledges the generous funding support from the RGC Collaborative Research Fund (Equipment) 2015/16 and the matching fund from the University. The project was led by Prof. Mansun CHAN (Former Director of the NFF) with Co-PIs from HKUST, HKU and CUHK.

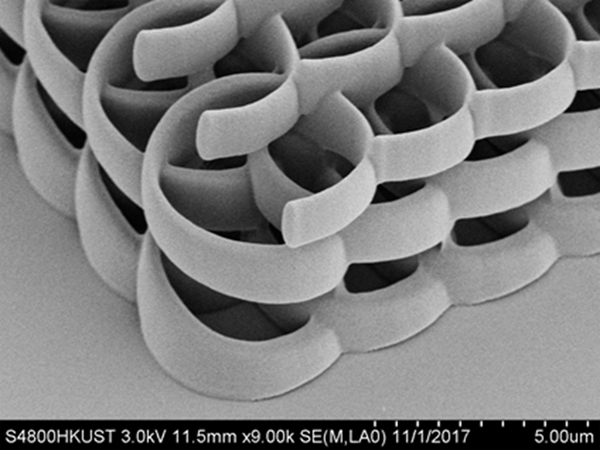

A Faster and Easier Way for Printing 3-D Micro-/Nano-Structures

The NFF welcomes the installation and launching of a new service by a state-of-the-art 3-D Laser Nano-Printer (“Nanoscribe”) in November 2017. The direct laser-writing technique for this 3-D printer is based on two-photon polymerization by ultra-short laser pulses. The laser lithography system exposes pre-defined paths of a photoresist, which after development results in self-supporting structures that are anchored to a substrate. This 3-D laser printer gives the NFF users a new tool to fabricate 3-D structures, which are otherwise difficult to be fabricated using conventional planar fabrication process.

The NFF acknowledges the generous funding support from the Research Equipment Competition (REC) fund in 2016/17. We also acknowledge the matching funds from DENG, DSCI, CBE, CHEM, ECE, MAE, PHYS and I2MS.

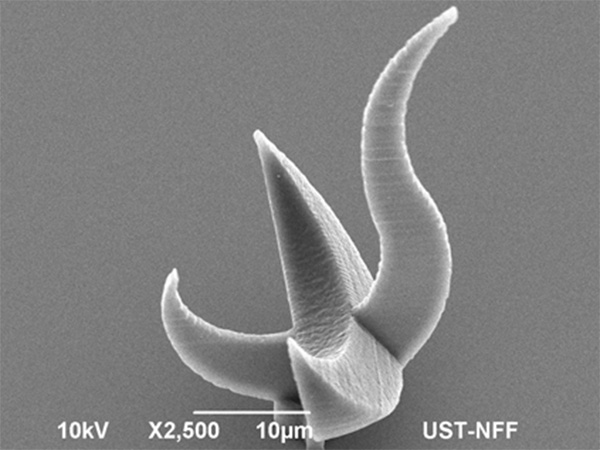

Scanning electron microscopy (SEM) pictures of the world’s smallest HKUST Sundial (“Red Bird”) printed on a glass substrate using the new 3-D laser nano-printer.

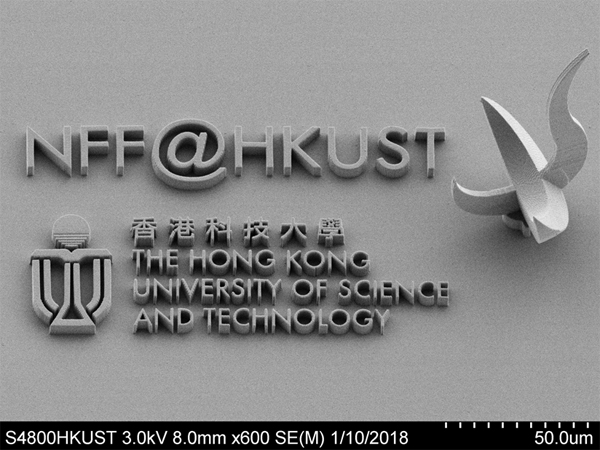

SEM picture of a test pattern produced during the installation and commissioning of the new 3-D laser nano-printer.

A Home-Built Reactive Ion Etching System

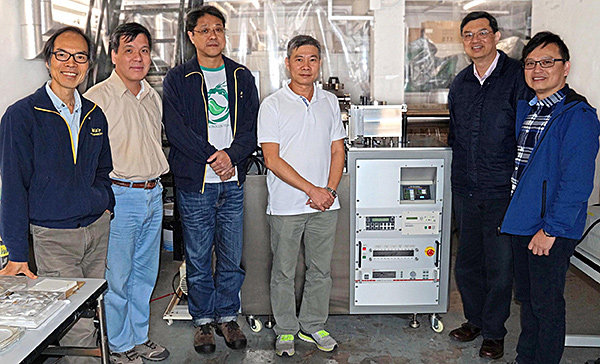

A team of the NFF technicians, led by Mr. Preason Man Wai LEE, Chief Technical Officer of the NFF, in collaboration with the Design & Manufacturing Services Facility (DMSF), has designed and built a new reactive ion etching (RIE) system for the NFF. On 5th December 2017, the NFF team and colleagues of the DMSF celebrated the completion of the machine development work. The NFF will be launching this new system for operation by mid-2018.